Introduction:

In recent years, the demand for high-quality PE pipes has significantly increased due to their durability, flexibility, and resistance to chemicals. As a result, industries such as agriculture, construction, and telecommunications heavily rely on PE pipes for water supply, drainage systems, cable installation, and more. However, the key to ensuring the production of reliable and efficient PE pipes lies in the machinery used. One such revolutionary machine is the High Performance Thick Board Making Machine - an extrusion machine with an extrusion mold for PE pipe production.

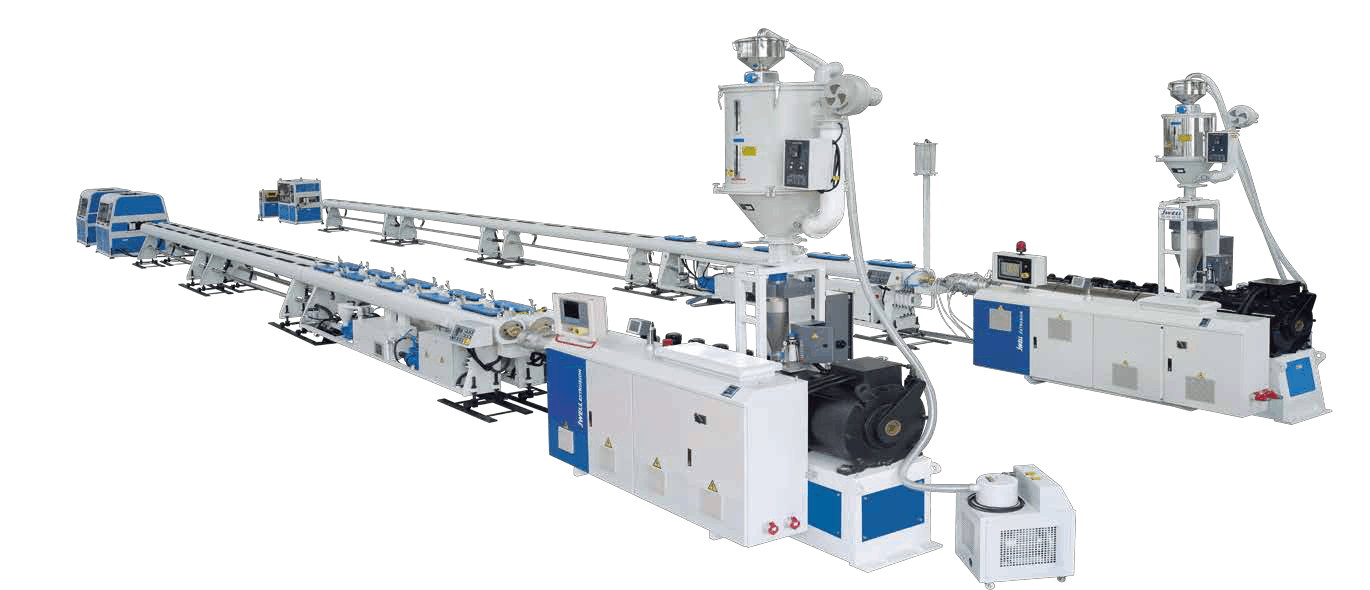

Expertly manufactured by JEEBO Machinery in China, the Qingdao JBD Machinery PE water supply pipe/gas pipe/oil pipe/heat preservation pipe production line is specifically designed to cater to the needs of various industries, offering seamless performance and consistent results. Let us delve deeper into the features and benefits of this remarkable machine.

1. Superior Design and Construction:

The High Performance Thick Board Making Machine boasts a state-of-the-art design that combines functionality with precision. The core component of this production line is the vacuum calibration tank, which ensures the accurate formation of the PE pipes' shape and dimensions. Additionally, the haul off unit and cutting mechanism enable uninterrupted production, allowing for maximum output while maintaining the quality of the pipes.

2. Versatile Application Possibilities:

This exceptional machine is capable of fulfilling a broad spectrum of applications, making it a versatile investment for various industries. Whether you need PE pipes for agricultural water supply and drainage systems, architectural water supply and drainage systems, or cable pavement, this production line has got you covered. Its unparalleled precision enables the creation of pipes suitable for diverse environments, including underground installations, harsh weather conditions, and even chemical-resistant applications.

3. Unmatched Efficiency and Performance:

The High Performance Thick Board Making Machine utilizes an extrusion process that ensures superior pipe quality and durability. With an extruder equipped with an extrusion mold, this production line guarantees consistent thickness and a smooth finish, resulting in pipes with exceptional strength and longevity. Moreover, the machine incorporates cutting-edge technology, enabling rapid production rates and minimizing downtime. This optimized workflow ensures maximum efficiency and productivity, benefiting manufacturers immensely.

4. Cutting-edge Innovation:

As technologies advance, it becomes crucial to invest in machinery that keeps pace with industry trends. The High Performance Thick Board Making Machine does precisely that. JEEBO Machinery prioritizes innovation, integrating the latest advancements into their design. By leveraging their expertise, they have successfully implemented cutting-edge features that enhance the overall performance of the production line, ensuring outstanding results, reduced waste, and increased profitability for manufacturers.

Conclusion:

Investing in a high-performance PE pipe production line is vital for industries relying on pipe systems. The High Performance Thick Board Making Machine provided by JEEBO Machinery surpasses industry standards, allowing for the efficient creation of PE pipes for various applications. Its versatile nature, coupled with its superior design, guarantee unmatched quality, durability, and performance. With this machinery, manufacturers can meet the increasing demands of diverse industries while maintaining a competitive edge.

Keywords: High Performance Thick Board Making Machine, PE pipe production, Qingdao JBD Machinery, efficient solution, PE water supply pipe, gas pipe, oil pipe, heat preservation pipe, vacuum calibration tank, haul off unit, cutting mechanism, versatile application, exceptional efficiency, cutting-edge innovation.