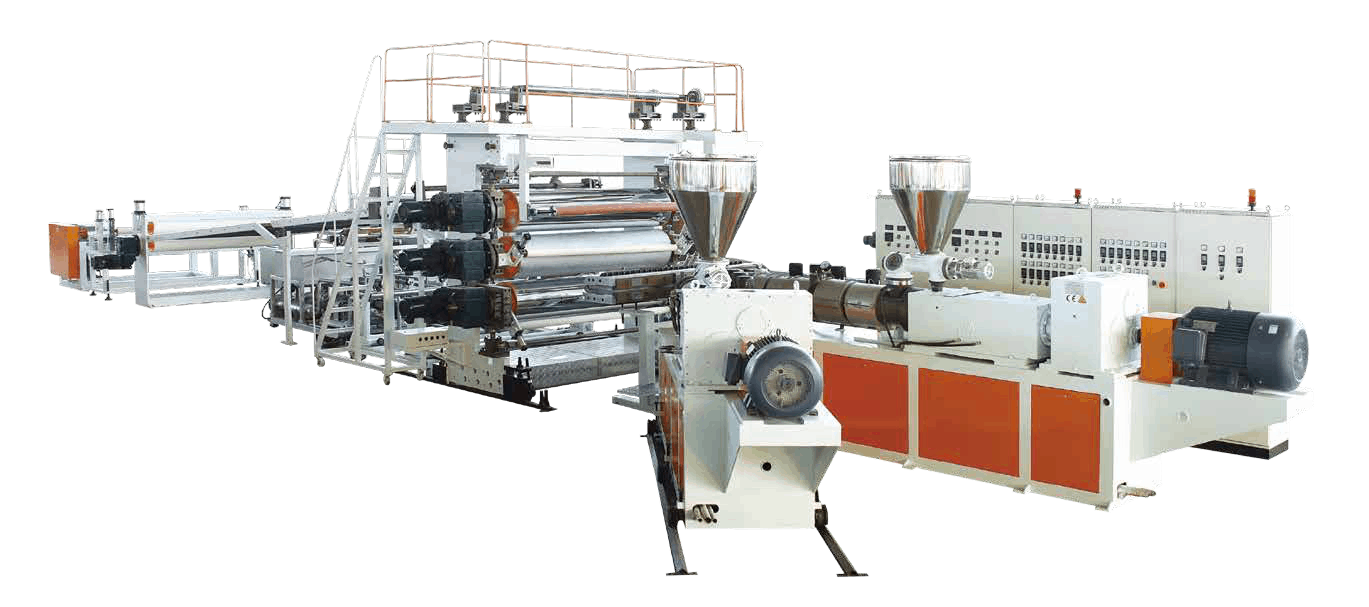

A sheet extrusion line is a manufacturing equipment used to produce extruded plastic sheets. This process involves melting plastic pellets and pushing them through a die, creating a continuous plastic sheet. The sheet can then be rolled or cut into various sizes and thicknesses for use in different industries.

Plastic Sheet Extrusion – Types and Usage

There are different types of plastic sheets, including PVC sheets, PP sheets, and HDPE sheets. PVC sheets are widely used for various applications, such as packaging, roofing, and construction, due to their durability and flexibility. PP sheets, on the other hand, are ideal for food packaging, thanks to their excellent heat-resistance and transparency. HDPE sheets are commonly used for construction and industrial applications, as they are tough and impact-resistant.

Sheet Extrusion Lines – Components and Features

A sheet extrusion line comprises several components, including a extruder, die, and cooling system. The extruder is responsible for melting plastic pellets and pushing them through the die, while the die shapes the melted plastic into a sheet. The cooling system cools down the hot sheet, ensuring it retains its shape and dimensions.

Modern sheet extrusion lines come with a range of features, including automatic controls, touchscreen interfaces, and high-speed outputs. They are designed for maximum efficiency and can produce large volumes of high-quality sheets at a fast rate.

PVC Sheet Extrusion Machine – Key Features and Benefits

PVC sheet extrusion machines are designed specifically for producing high-quality PVC sheets. They come with features such as advanced cooling systems, high-speed outputs, and automatic controls. Some of their key benefits include:

- Durability: PVC sheets produced using PVC sheet extrusion machines are highly durable, making them ideal for industrial and construction applications.

- Flexibility: PVC sheets are flexible and can be easily shaped and molded to suit specific needs.

- Low-maintenance: PVC sheet extrusion machines are easy to maintain, reducing the need for regular servicing and downtime.

- Cost-effective: The high-speed outputs of PVC sheet extrusion machines make them cost-effective, as they can produce large volumes of sheets at a faster rate.

Conclusion

Sheet extrusion lines are essential manufacturing equipment for producing plastic sheets for various industrial and commercial applications. PVC sheet extrusion machines are specialized equipment designed for producing high-quality PVC sheets. Investing in a sheet extrusion line or PVC sheet extrusion machine is a wise decision for businesses looking to produce high-quality plastic sheets at a fast rate and at a low cost.