Plastic sheet extrusion is a highly specialized process that requires precision and accuracy. This process has evolved over the years to include new technologies and equipment that can produce high-quality sheets with excellent mechanical properties. One such technology is profile extrusion, which is used to produce complex profiles with varying cross-sections.

Profile extrusion is a type of extrusion process that involves extruding a material through a die that has a shape of the final product. This process is used to produce customized profiles such as pipes, tubing, and building materials. Profile extrusion is preferred over other types of extrusion processes because it can produce a high degree of precision, consistency, and repeatability.

The demand for sheet extrusion lines has increased significantly in recent years due to the increased demand for high-quality plastic sheets. Plastic sheets are widely used in various industries, and their versatility makes them an excellent choice for several applications. The use of plastic sheets has many benefits, including lightweight, durability, weather-resistant, and cost-effectiveness.

The plastic sheet extrusion process involves several steps that include melting the plastic material, extruding it through a die, cooling the sheet, and cutting it to the desired length. The extruded sheet can be further processed by adding coatings, laminates, or printing. The final product is then packaged and shipped to the customer.

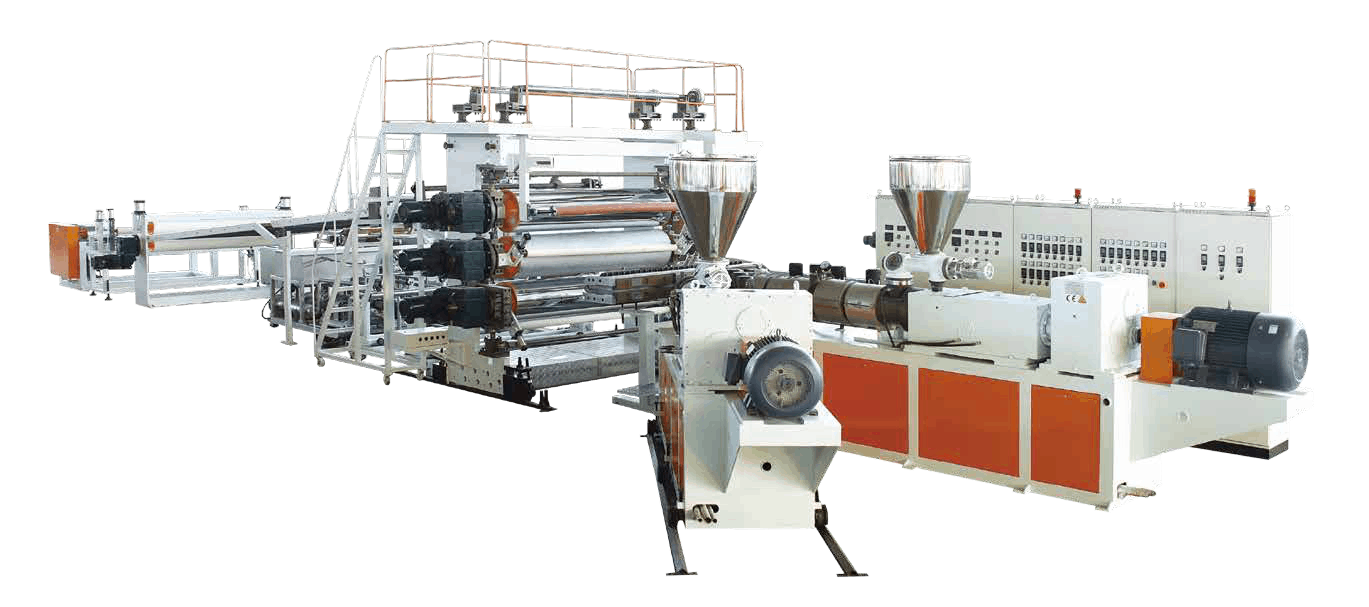

Sheet extrusion lines are available in various configurations, depending on the material being used and the final product specifications. PVC sheet machines, PP sheet extrusion lines, and PVC sheet extrusion lines are some of the common types of sheet extrusion lines available in the market. Each type of extrusion line is designed to work with specific materials and produce specific types of products.

Plastic sheet extruders are essential for manufacturers in the plastic industry. They invest heavily in technology and innovation to produce high-quality sheets that meet the customer's needs. As the demand for plastic sheets continues to increase, so will the need for advanced and more efficient sheet extrusion lines.

To conclude, sheet extrusion lines play a crucial role in the plastic manufacturing industry. The process of extruding plastic sheets requires precision, consistency, and accuracy to produce high-quality products that meet customer specifications. Profile extrusion is an innovative technology that enables manufacturers to produce complex profiles with varying cross-sections. As the demand for plastic sheets continues to grow, there will be a need for more advanced and efficient sheet extrusion lines to meet the customer's needs. If you are looking for quality plastic products, it is essential to choose a reputable manufacturer with a proven track record of producing high-quality products.