TECHNICAL PARAMETERS

Pipe diameter(mm) 50,75,90,110,160 75,90,110,160,200,250 Extruder(for middle layer) 65/132 80/156 Extruder (for outer& inner layer) 65/132 or 55/120 65/132 Length of vacuum tank(mm) 6000 6000 Haul-offs machine 3claw 3claw Cutting machine planetary cutting planetary cuttingProduced PPR Pipe

Co-extrusion is sending two or more molten raw materials through one die and producing a multi-layer pipe which can have various colors or wall thickness. When multiple plastics are combined, the result can yield properties distinct from those of a single material. Multi-layer extrusion has opened up new frontiers in material engineering and addressed several previously difficult manufacturing needs. Co-extrusion can also reduce costs by using recycled and reground scrap inside virgin material for handrails, fences and other applications. The process can be seen in projects as diverse as pipe and structural components or air blown food containers.Description of the co-extrusion line

Video

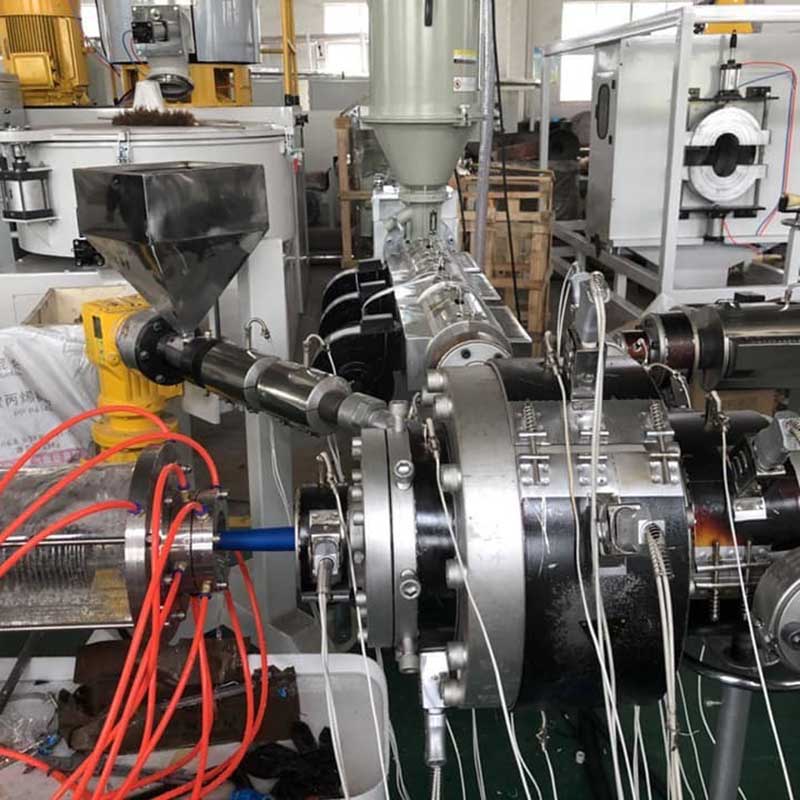

The Complete Extrusion Line Is Composed Of The Following Items: 1.Single screw extruder 2.Co- extruder: manufacturing marking line on pipe or multilayer of pipes 3.Die head 4.Vacuum tank: due to diameter, it can be designing of single, double vacuum chamber 5.Cooling tank: due to diameter, the numbers of cooling tank can be one, two or three 6.Haul-offs: due to diameter, it can be designing of double, three, four, six, eight, ten, twelve caterpillars 7.Cutter: due to diameter, it can be designing of no-scraps cutter or planetary cutter 8.Coiler/Tipping chute

The Complete Extrusion Line Is Composed Of The Following Items: 1.Single screw extruder 2.Co- extruder: manufacturing marking line on pipe or multilayer of pipes 3.Die head 4.Vacuum tank: due to diameter, it can be designing of single, double vacuum chamber 5.Cooling tank: due to diameter, the numbers of cooling tank can be one, two or three 6.Haul-offs: due to diameter, it can be designing of double, three, four, six, eight, ten, twelve caterpillars 7.Cutter: due to diameter, it can be designing of no-scraps cutter or planetary cutter 8.Coiler/Tipping chuteProduct detail