Processing Process

Raw Material—mixer—conical twin screw extruder—mould and calibrator—vacuum forming machine— spraying cooling machine—haul-off machine—cutting unit—belling machine—stacker.

| Model | 50B | 50C | 63B |

| Pipe Range (mm) | 16-50 | 16-50 | 16-63 |

| Screw Model | 51/105 | 65/132 | 65/132 |

| Throughput (kg) | 200 | 250 | 280 |

Mixer

Optimized design by experienced engineer

Self-friction as the heating source, energy efficiency as result

Vaccum suction loading for low noise and no-dust working situation

Spiral loading after mixing for keeping mixture composition

Automatic Heating and Reloading

Specifications

Video

Line Details

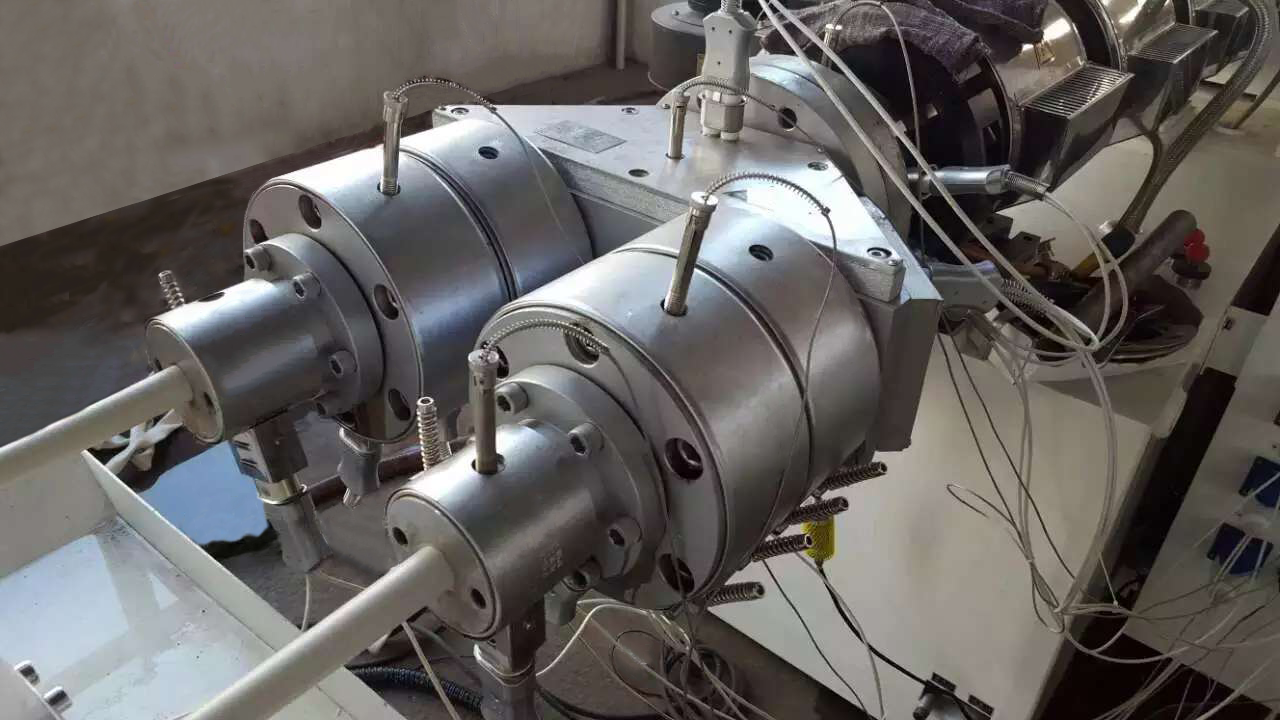

Conical Twin Screw Extruder

Special design for gentle processing of PVC powder

permanent magnet synchronous motor for reducing around 10% energy consumption comparing with DC or AC Motor.

Operator oriented operation logic for clever and easy operation during production

Touch screen (optional) for an integrated information management and easy operation

Mould

Specially design for flow channel for superb pipe shaping and reasonable melt pressure.

The large compression ratio ensures the excellent plasticizing effect.

Vacuum Calibration & Cooling

Separately cooling system for double strand with independent pumps system.

frequency conversion vacuum control system for constant vacuum environment with lowest energy consumption.

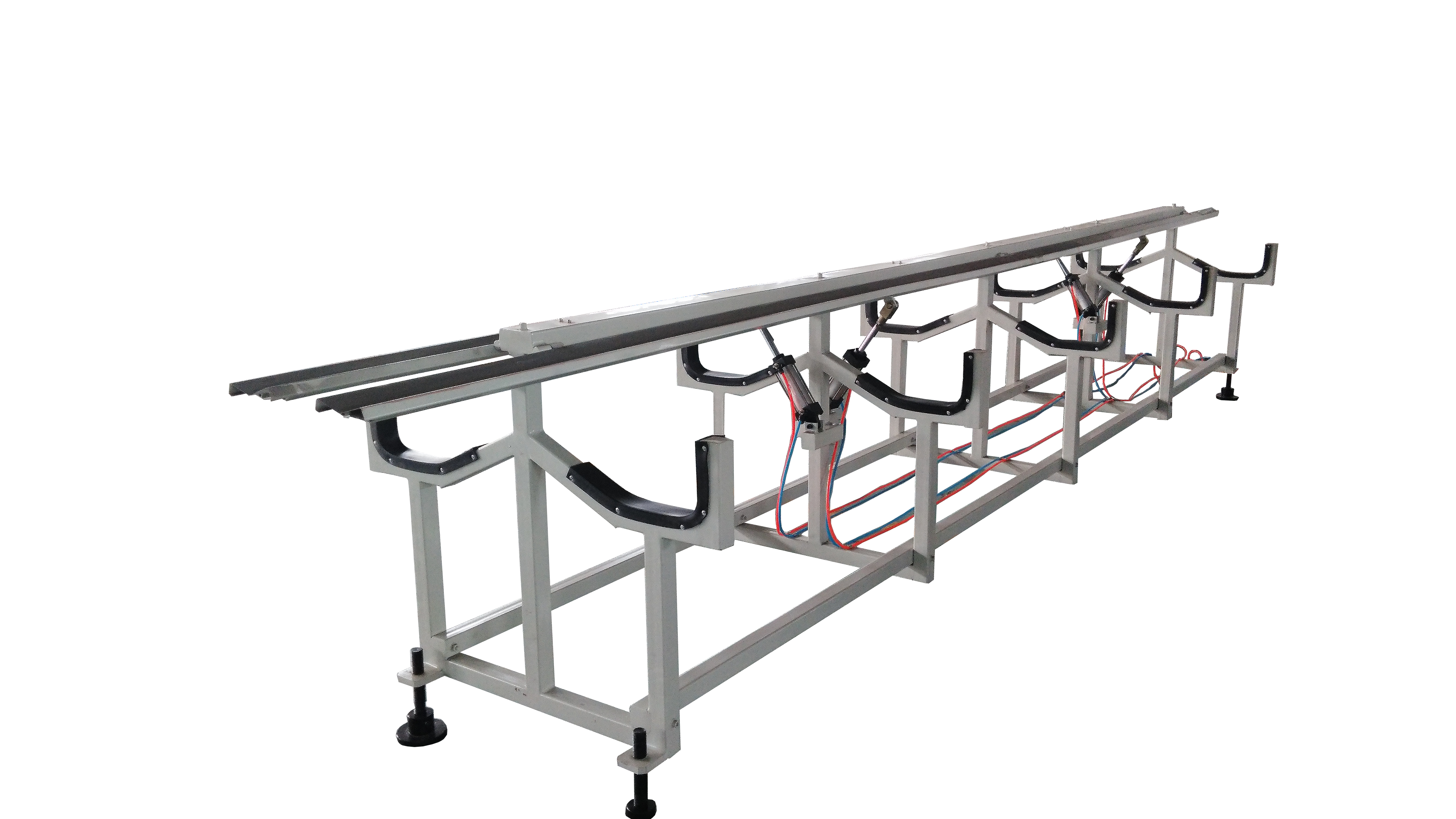

Haul-off & cutter combination

Servo Motor and high-quality reducer for synchronized movement of belt or caterpillar

Customized hauling concept adopted based on certain production requirement

Suitable cutting concept based on production requirement

high accuracy encoder ensures a precise and stable cutting length

Hauling-off and cutting combination is optional with the advantage of space saving.

Belling

Two heating position for on-time belling by high line speed

Energy saving by automatic switch of heating element

Customized cooling concept based on production requirement

Pneumatic Stacker

Stable stacker structure and pneumatic driven for pipe reloading

Moving action controlled by PLC program

Separate control for both extrusion strand

Detailes and Produced product