Processing Process

Raw Material—feeder—single screw extruder—mould and calibrator—vacuum forming machine— spraying cooling machine—haul-off machine—cutting unit— stacker.

| Model | LB630 | LB800 | LB1200 | LB1400 |

| Pipe Range (mm) | 315-630 | 500-800 | 630-1200 | 710-1400 |

| Throughput(kg) | 850 | 1100 | 1200 | 1400 |

Specifications

Video

Product detail

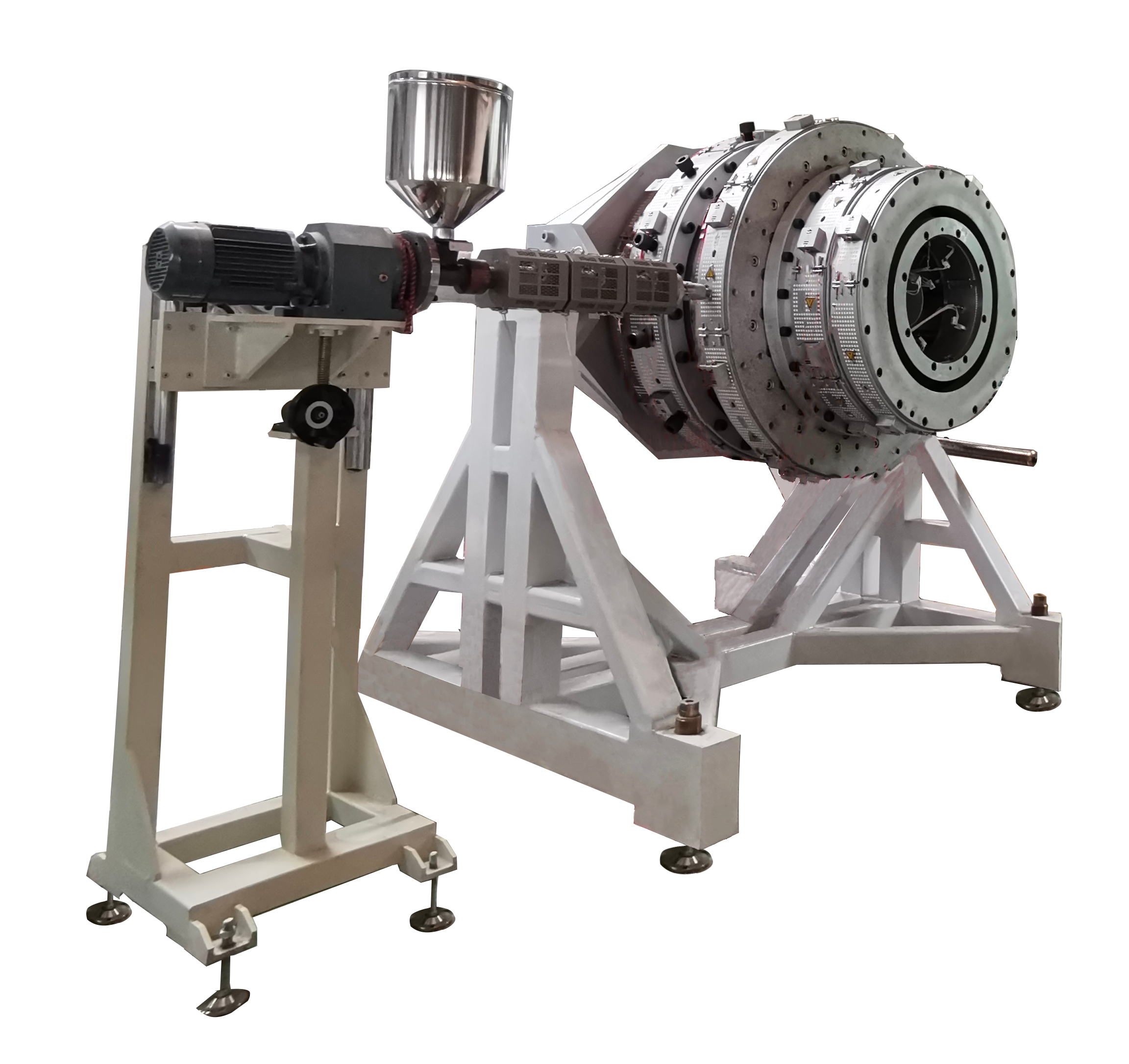

Mould Specially designed of flow channel for superb pipe shaping and reasonable melt pressure. The large spiral distributor ensures the excellent plasticizing effect.

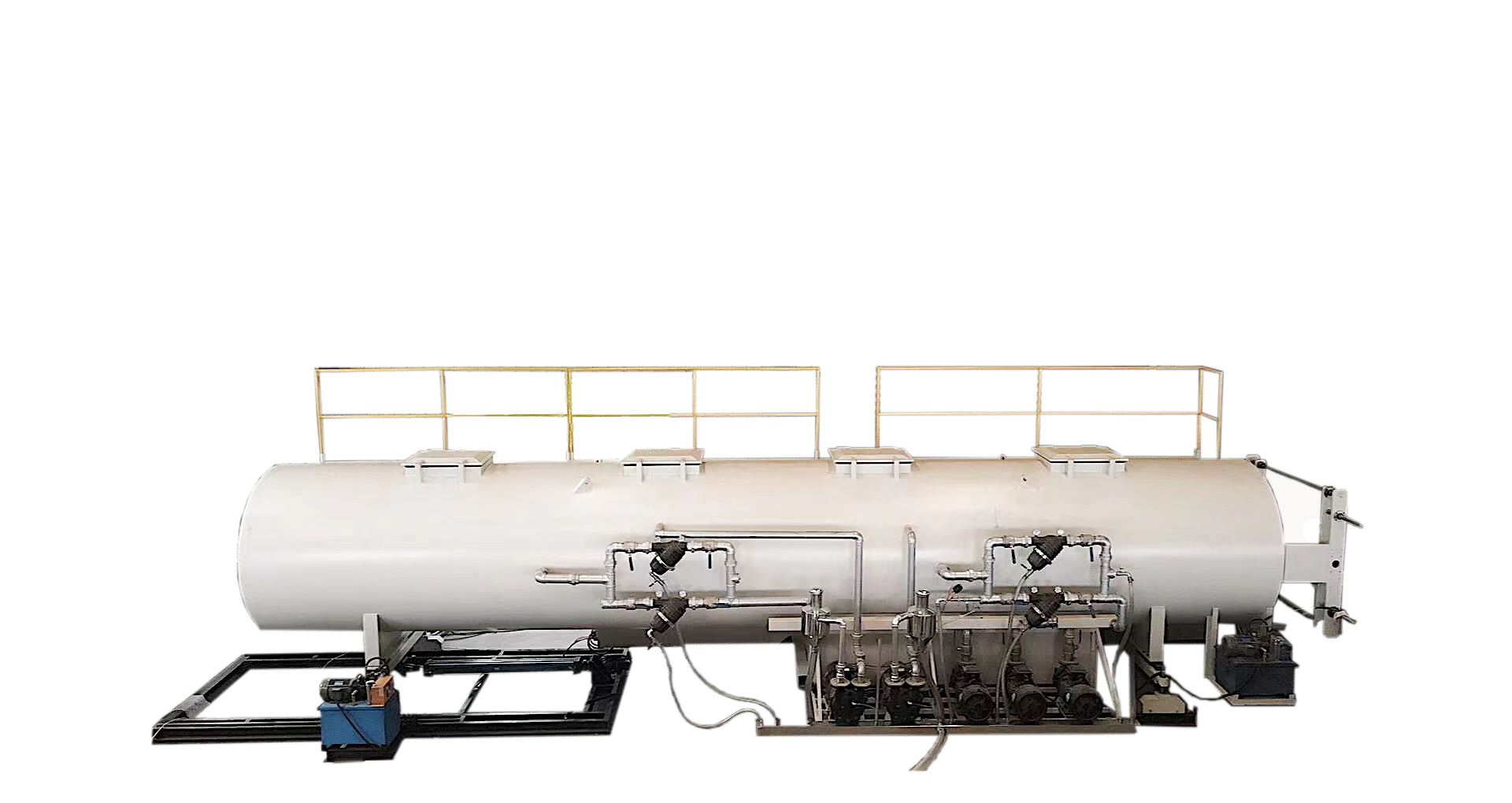

Mould Specially designed of flow channel for superb pipe shaping and reasonable melt pressure. The large spiral distributor ensures the excellent plasticizing effect. Vacuum Calibration & Cooling Frequency conversion vacuum control system for constant vacuum environment with lowest energy consumption. Backup pumps for each section of vacuum tanks to ensure a reliable production Easy operation and clear display layout Robust concept of components for stable running

Vacuum Calibration & Cooling Frequency conversion vacuum control system for constant vacuum environment with lowest energy consumption. Backup pumps for each section of vacuum tanks to ensure a reliable production Easy operation and clear display layout Robust concept of components for stable running  Spraying Tank Energy Efficiency pump and enlarged water tank for sufficient cooling effect High quality part, robust structure design ensures a long service time

Spraying Tank Energy Efficiency pump and enlarged water tank for sufficient cooling effect High quality part, robust structure design ensures a long service time Haul-off Unit Servo Motor and high-quality reducer for synchronized movement of belt or caterpillar Ten caterpillars haul off for hauling off of different pipe diameter Tailored hauling concept adopted based on production requirement of customers Easy maintenance mechanical concept

Haul-off Unit Servo Motor and high-quality reducer for synchronized movement of belt or caterpillar Ten caterpillars haul off for hauling off of different pipe diameter Tailored hauling concept adopted based on production requirement of customers Easy maintenance mechanical concept  Cutting Unit Double cutting concept for different production requirement high accuracy encoder ensures a precise and stable cutting length Hauling-off and cutting combination is optional with the advantage of space saving.

Cutting Unit Double cutting concept for different production requirement high accuracy encoder ensures a precise and stable cutting length Hauling-off and cutting combination is optional with the advantage of space saving. Electrical Pipe Holder The electrical motor for adjustment of the height of holder. robust structure of holder for stable pipe holding for further transportation of pipes

Electrical Pipe Holder The electrical motor for adjustment of the height of holder. robust structure of holder for stable pipe holding for further transportation of pipes