Specifications

| Model | LB180 | LB240 | LB300 | LB600 |

| Max width of products(mm) | 180 | 240 | 300 | 600 |

| Screw Model | SJ55/110 | SJ65/132 | SJ65/132 | SJ80/156 |

| Motor power | 22KW | 37KW | 37KW | 55KW |

| Cooling Water(m3/h) | 5 | 7 | 7 | 10 |

| Compressor(m3/h) | 0.2 | 0.3 | 0.3 | 0.4 |

| Total length(m) | 18m | 22m | 22m | 25m |

Product detail

Plate Mould

We offer double Strand mould for the PVC trunking production line. By this way, the productivity will be highly improved. The optimized channel design ensures high flow performance. The advanced plate mould produced the profile with high precision.

Conical Twin Screw Extruder

Conical Twin Screw Extruder The screws are specifically designed and manufactured for the processing of dry pvc powder blend. Our conical twin screw extruder design cater to the raw materials feature ensuring homogeneous mixture, better plastification and conveying efficiency. The permanent magnet synchronous motor provide high energy efficiency for the extruder. Equipped with PLC control system, it realized controlling the whole production line in the one site.

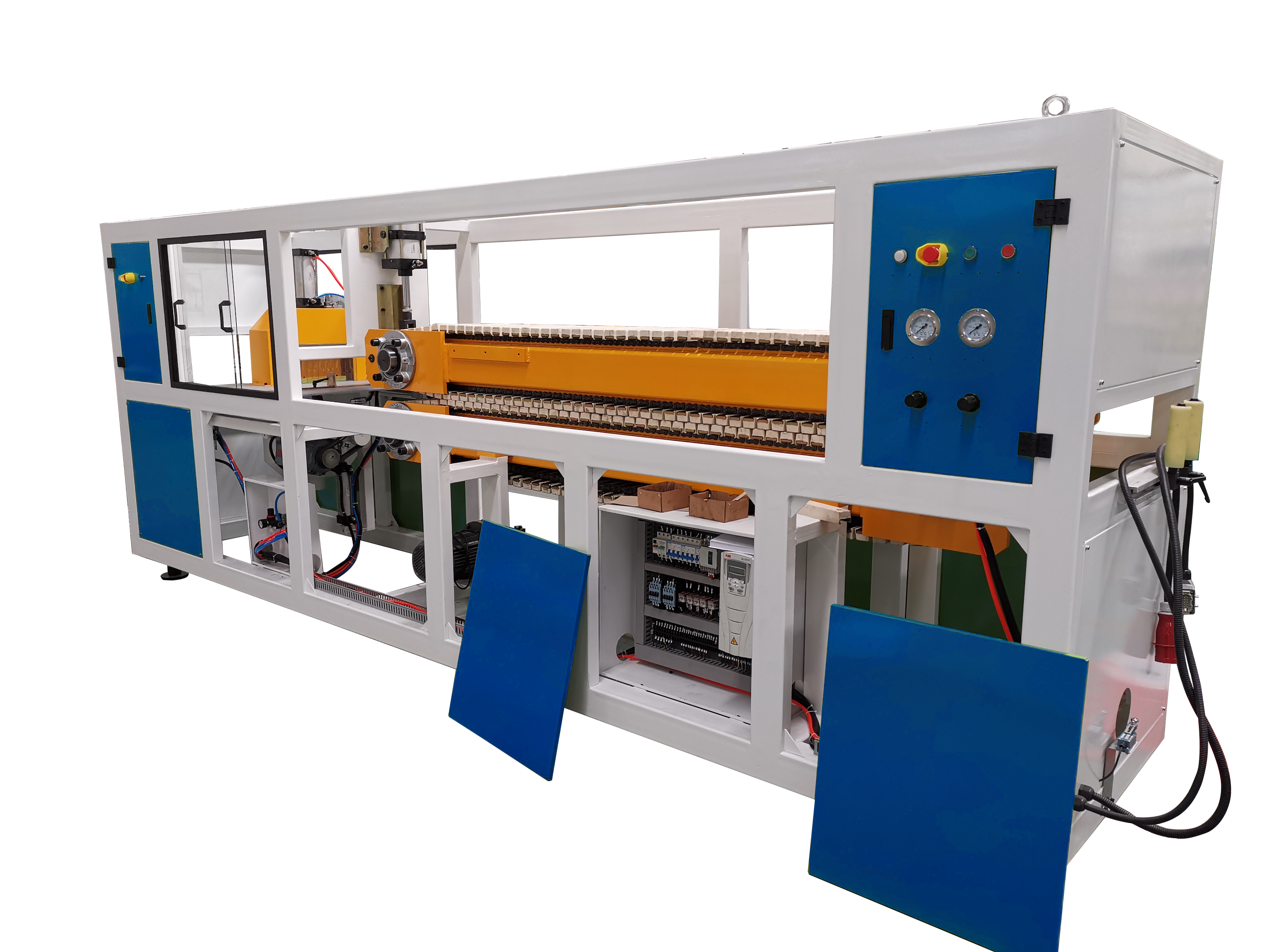

Haul-off & Cutter Combination

The force distribution along each caterpillars has sufficient hauling force. We offer good-quality rubber for the haul-off machine. The pneumatic pressure is conducive to the easy adjustment and product protection. Two kinds of cutting way including swarfless and saw cutting are available for customization.

Calibration table

The calibration table has stable steel frame and the whole body material is SUS 304 stainless steel. We have multi-dimension position adjustment system. With precious layout of water pumps and vacuum calibrator, the PVC profile will be rapidly shaping and cooling. Enough length of the calibration table ensures the shaping of the PVC profile

Processing Process

The process flow of this line is PVC powder + additive — mixing—material feeder—twin screw extruder— mould and calibrator—vacuum forming table—haul-off machine—cutting machine—discharge rack.

This PVC profile extrusion line adopts conical twin screw extruder, which is suitable for both PVC powder and PVC granules. It has degassing system to ensure the excellent material plasticization. The high speed mould is available, and it can largely increase the productivity.

Video