What does vacuum and cooling tanks do?

Vacuum and cooling tank is the essential part of the pipe production. It depends the quality and shape of the product. The melt plastic through the die-head move into the vacuum and cooling tank. Through continuous water washing and vacuum sizing, the melt plastic cooled and shaped. It is the basic of the following hauling and cutting. For better vacuum shaping, we offer two stage vacuum tanks for bigger diameter product.

Optional

➢ Frequency inverter: ABB/Siemens inverter ➢ Backup vacuum & water pumpsProduct detail drawing

Electrical conbinet

Flowmeter

Gas water separator

Roundness correction

Surface of vacuum tank

Water inflow control

Vacuum& Cooling tank Components

➢ Holder Out of the die-head, the product is soft and easily deformed. Holder is conducive to the moving of the product.

➢ Vacuum & water pump We offer MINAMOTO vacuum& water pumps. It is worldwide famous brand of the pump. In the working process, it has excellent performance and long lifetime.

➢ Water tank We offer huge water tank storing colder water for the water spraying.

➢ Spraying system 12-channel spray system with several nozzles was provided. Giving the product enough cooling time and getting good effect.

➢ Water recycling system The water pumps out from the water tank and finally back to the tank. It provides continuous working experience.

➢ Positional control system Applying leverage principle, the position control system makes the huge machine easy moving.

Water level control

Water Pump

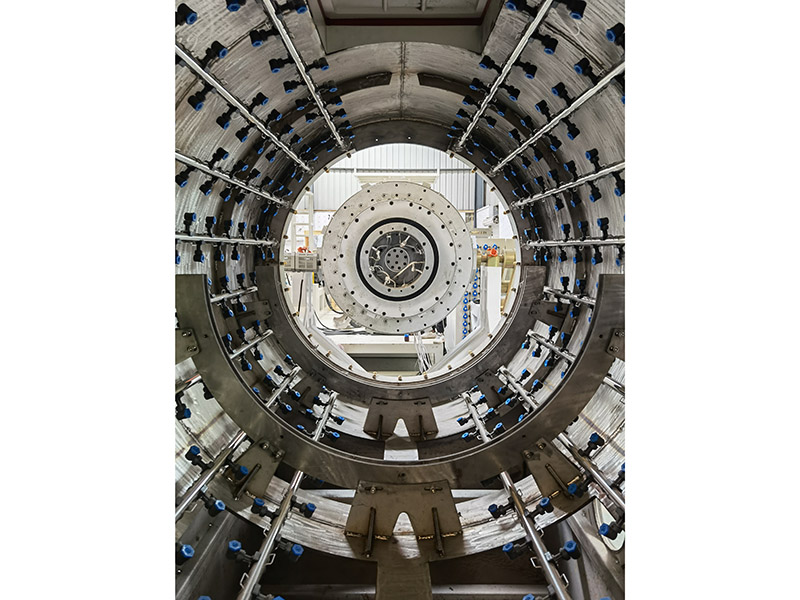

Vacuum tank inner